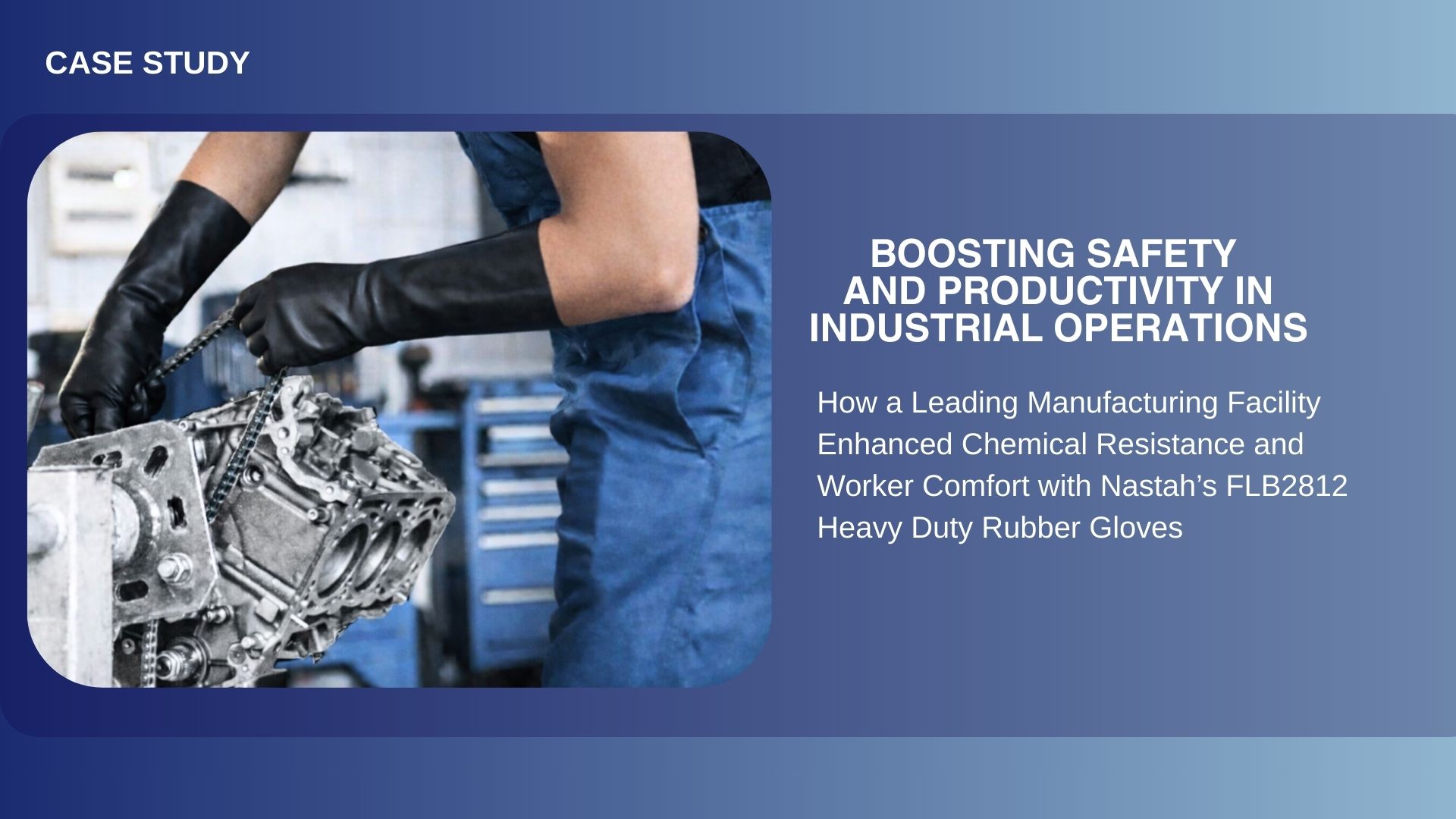

How a Leading Manufacturing Facility Enhanced Chemical Resistance and Worker Comfort with Nastah’s FLB2812 Heavy Duty Rubber Gloves

Background

A large industrial manufacturing facility in Europe was seeking to strengthen its chemical protection and mechanical durability standards across multiple departments, including maintenance, cleaning, and production support.

The facility operates in environments with frequent exposure to oils, solvents, and cleaning agents, and requires gloves that can withstand long hours of use, high contact abrasion, and chemical hazards, without compromising worker comfort.

The Challenge

The facility’s existing gloves provided basic hand protection but suffered from premature wear and tear, especially during contact with industrial solvents and lubricants.

Key challenges included:

- Frequent glove replacements due to chemical degradationand abrasion

- Grip slippagewhen handling oily tools and parts

- Operator hand fatigueduring extended shifts

- Delays caused by difficulty donning and removing glovesquickly

- Struggles to meet local and EU PPE compliance standards

The company’s HSE (Health, Safety & Environment) division needed a glove solution that delivered superior durability, chemical resistance, and ergonomic comfort, while remaining fully certified for industrial safety.

The Solution: Nastah FLB2812 Heavy Duty Rubber Gloves

After evaluating several PPE options, the facility selected Nastah’s FLB2812 Heavy Duty Rubber Gloves, a Type A chemical protective glove engineered for high-risk industrial use.

Constructed from premium natural rubber and cotton flocklined interior, these gloves offer a powerful combination of protection, comfort, and efficiency.

Key Advantages

- High Chemical & Oil Resistance:Excellent resistance to acids, alkalis, and oils—protecting workers in chemical, automotive, and maintenance operations.

- Enhanced Grip:Diamond-patterned palm ensures a secure hold, even on wet or oily surfaces, reducing the risk of slippage and accidents.

- Heavy-Duty Durability:71mm (28 mil) thickness provides strong barrier protection against abrasion and puncture.

- Comfort & Convenience:Cotton flocklined interior absorbs moisture and minimizes hand fatigue during prolonged wear.

- Easy Donning & Doffing:Wide cuff design allows for quick glove changes, improving workflow efficiency.

-

Certified Protection:

- EN Standard Certified (EU)

- SIRIM DOSH Certified (Malaysia)

- Type A PPE Category 3compliance for high-risk environments

Implementation

The FLB2812 gloves were introduced across departments with chemical handling, degreasing, and heavy maintenance activities.

A 2-month field trial was conducted to measure performance in real working conditions, focusing on durability, comfort, and chemical resistance.

Deployment Areas:

- Maintenance workshops and repair units

- Chemical cleaning and degreasing sections

- General plant operations and machine servicing

Results

The upgrade to Nastah’s FLB2812 gloves produced significant safety and productivity improvements:

1. Average Glove Lifespan

Previous gloves lasted 5 days.

FLB2812 lasts 9 days — delivering 80% longer usage.

2. Chemical Resistance

Previous gloves offered moderate resistance.

FLB2812 provides excellent resistance, ensuring higher protection.

3. Grip Efficiency

Previous gloves had inconsistent grip.

FLB2812 features a strong, non-slip grip, resulting in fewer handling errors.

4. Operator Comfort

Previous comfort score: 7.5 / 10.

FLB2812 comfort score: 9.0 / 10 — a 20% improvement.

5. PPE Compliance

Previous gloves: Partial compliance.

FLB2812: Fully certified, meeting EN & SIRIM DOSH standards.

Audit Result: The facility achieved full compliance with PPE Category 3 and EN standards, while reducing glove wastage and improving worker satisfaction.

Feedback from the Field

“Our maintenance team reported a clear difference in grip and comfort. The gloves lasted longer and resisted solvents much better than previous brands. We’ve reduced downtime from glove changes and improved safety confidence overall.”

Conclusion

By upgrading to Nastah FLB2812 Heavy Duty Rubber Gloves, the manufacturing facility achieved:

✅ Improved protection against chemicals and oils

✅ Reduced glove replacement costs

✅ Higher comfort and compliance in line with EN and SIRIM standards

✅ Greater productivity and efficiency in maintenance operations

Product Overview

Material: Natural Rubber

Lining: Cotton flocklined

Thickness: Approximately 0.71 mm (28 mil)

Length: Approximately 320 mm (12.5 inches)

Available Sizes:

7 (Small), 8 (Medium), 9 (Large), 10 (Extra Large)

Colour: Black

Cuff Design: Wide cuff

Classification: PPE Category 3 – Type A Chemical Protection

Certifications: EN Standard, SIRIM DOSH (Malaysia)

Ready to Reinforce Your Industrial Safety Program?

Empower your workforce with Nastah FLB2812 Heavy Duty Rubber Gloves — trusted for performance, protection, and comfort in demanding industrial environments.

📩 Contact our sales team: sales@nastah.com.my

🌐 Learn more: www.nastah.com.my